Plastic Division

Plastics is the right hand of KCL and we know our plastic very well. A healthy number of machines and labor to produce and do finishing until each and every piece is perfected. We have ISO 22000 certified production facility. There are three types of molding products that we offer our customer:

Extrusion Blow Molding

This department is running machines with single, double and triple heads with options of double stations, 05 machines Automatic ( Make Akei) with a capacity of making products ranging from dropper pump/30 ml bottle/jar to 10 ltr Jerry cans/containers, machines have capacities of parison controls and visual strip for packed product view, this system is fully supported with a professional experienced machines operators along with 7 tons chiller and 4-18 kgs 3 crushers.

Stretch Blow Molding (Pet)

SBM division includes 5 Automatic machines ( 04 single stage make Nissie ASB Japan – 01 double stage make Chum Power Taiwan).Product Capacity from 30 ml bottle to 10 ltr containers, production leads up to 40000/day in case of specific design and weights of products.

Injection Molding

Currently 18 injection machines of different capacities are in working ranging from 90 tons to 228 tons with a short weight capacity of 89 grams to 405 grams supported with 4 chillers on injection floors from 3 tons to 8 tons. We are running both cold runner and hot runner molds.

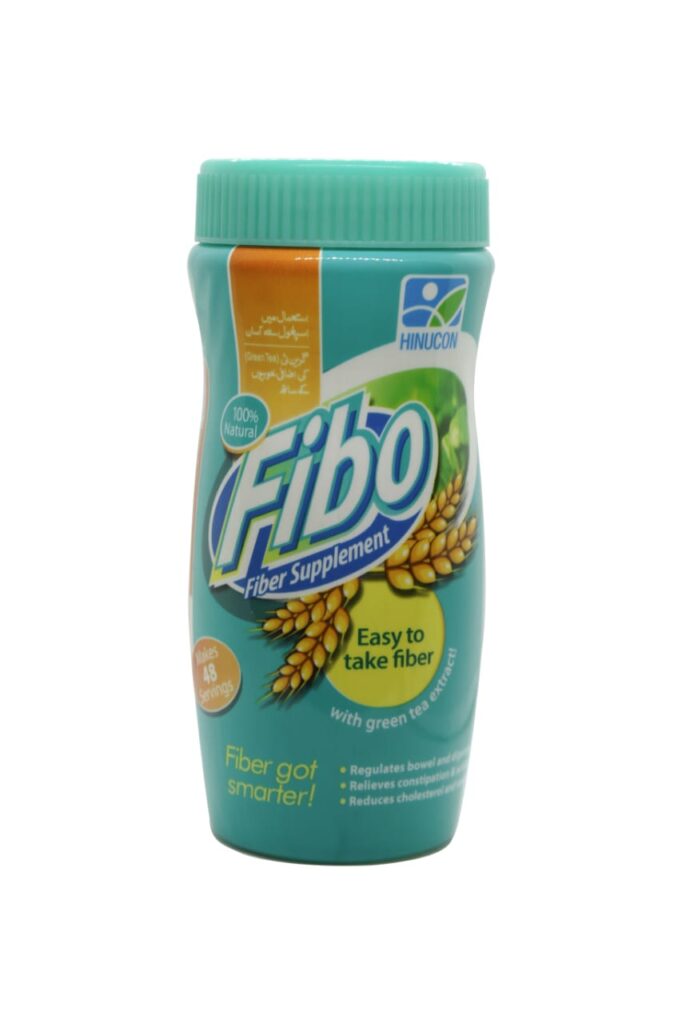

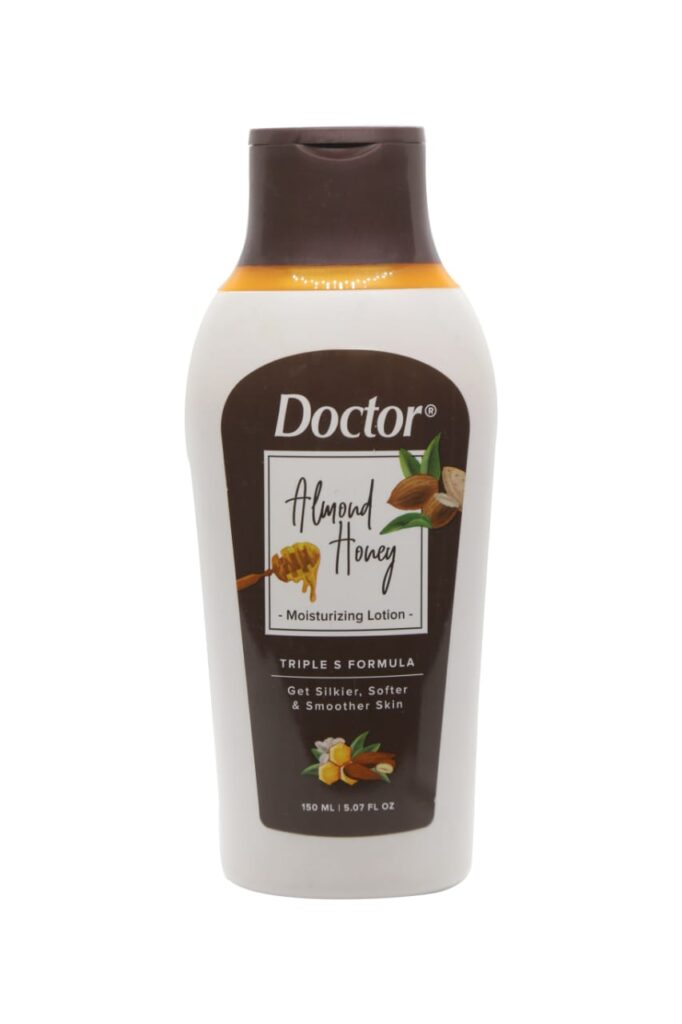

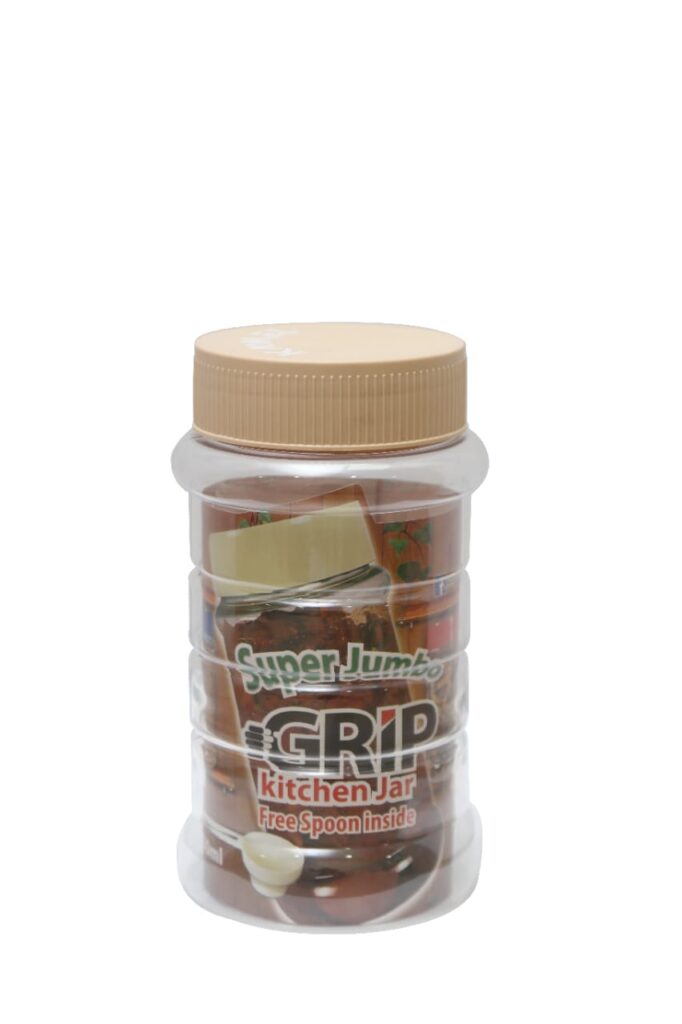

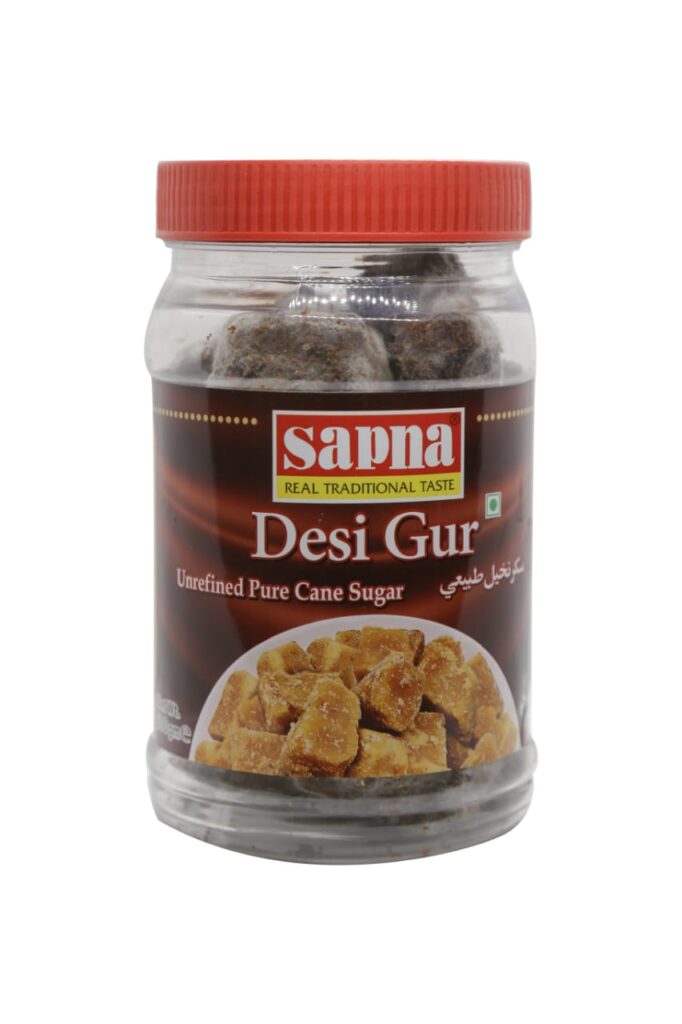

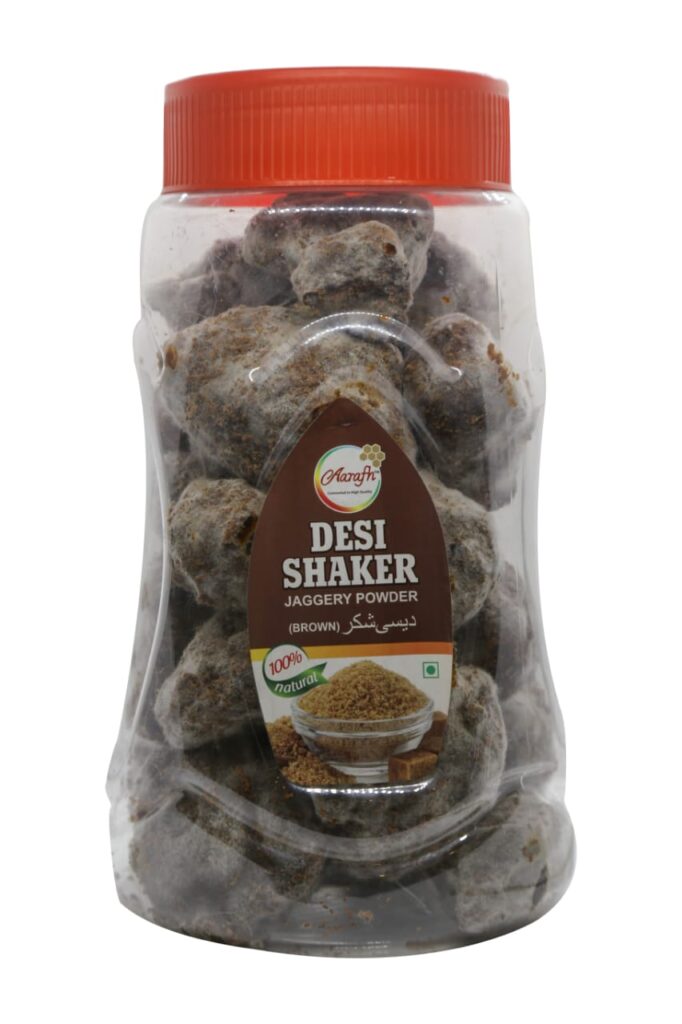

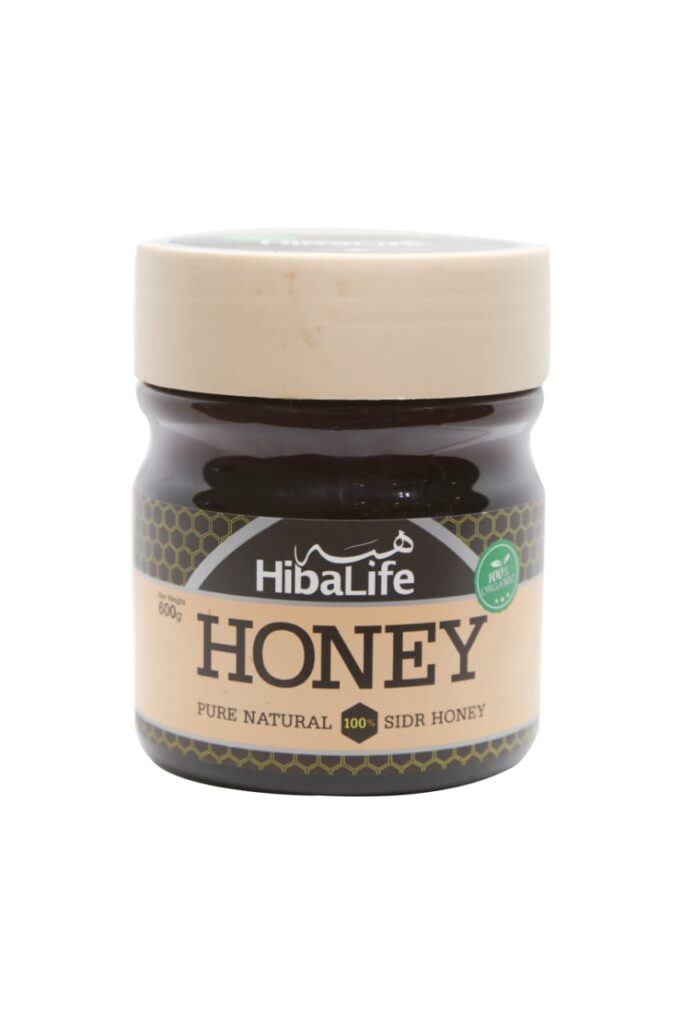

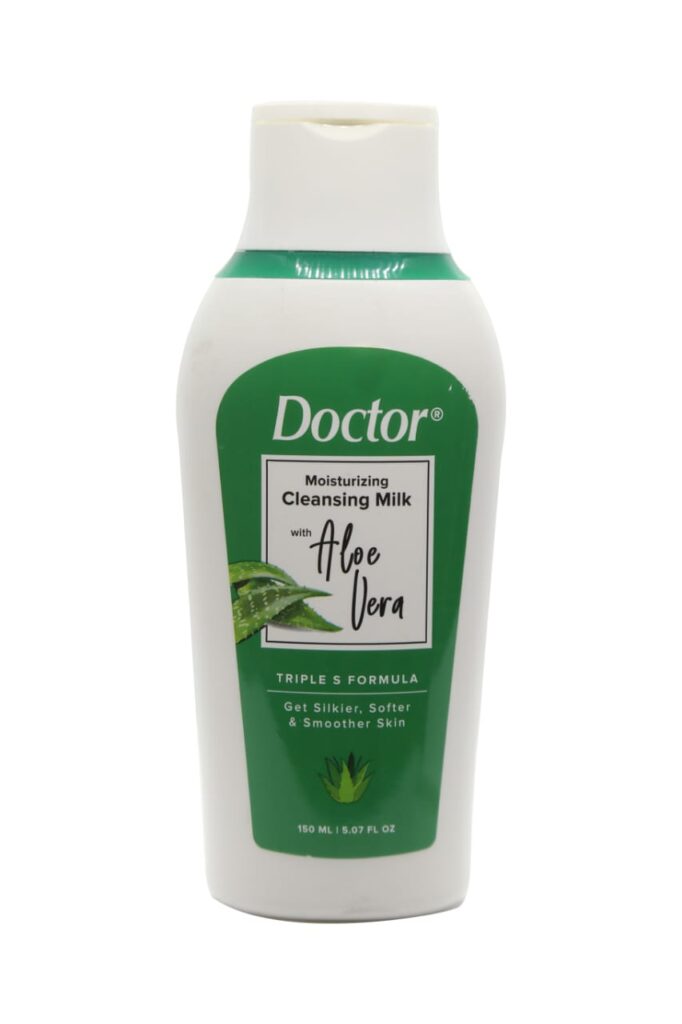

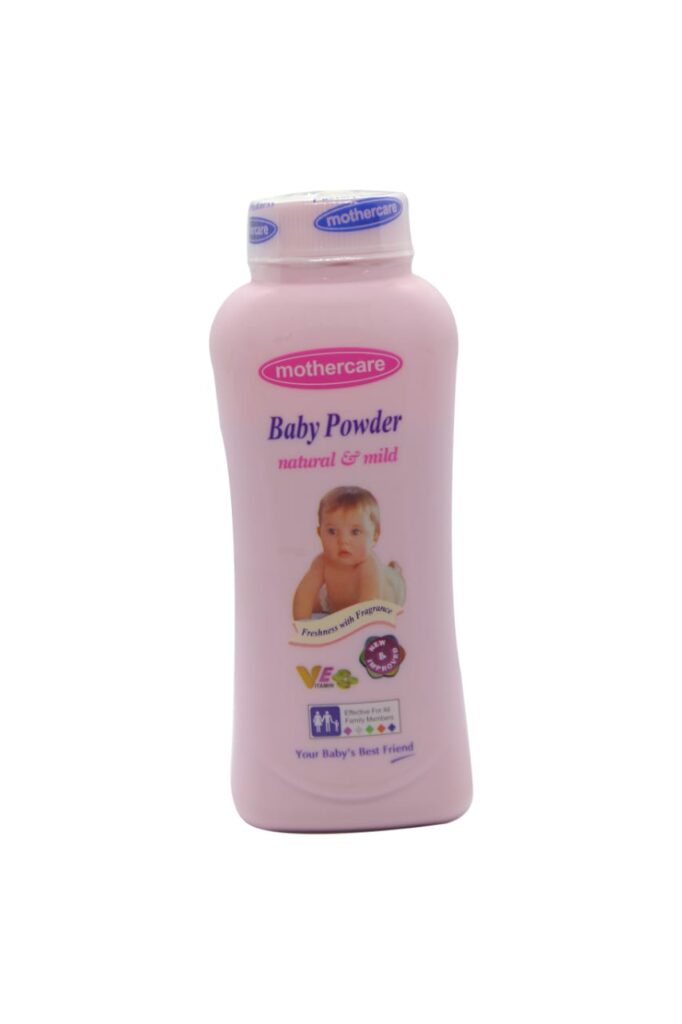

An attractive range of products is already offered in which products can be packed and sold.

for more product visit product gallery

Research & New Development

At KCL we understand product development and the critical role for Research & Development plays in helping our customers get a component your product that is highly manufacturable. KCL dedicated R&D division provides controlled access with guaranteed confidentiality in collaborating with our customers on new products.

Quality Production

KCL has the facility to design and develop products starting from sketches, drawings, prototypes to molds that give final products to meet customer’s requirements. In designing products, various softwares are used such as PRO-Engineer (Creo Parametric 2.0), Solid Works, AutoCAD, & MoldFlow.

Quality Assurance & Compliance

Provides a working template for a high-cavitation production process Allows for onsite testing, engineering changes, and product evaluation prior to production at production plants Provides speed to customer response with greater market share and profitability.

Supply Chain Management

Material Flow Analysis. “Proof of Principle” to ensure your products meets the optimum manufacturability and functionality that you require to excel in any market offering. We at KCL ensure that such an achievement is a dual relation between us as your product offering company and you as the market solution company, which will allow…